LASER MEASUREMENT AND DATA ANALYSIS

Laser Measurement combined with computer analysis of data real applied metrology

Prime Machine’s skilled technical craftsmen are able to laser measure objects the size of airplanes to miniature fasteners. The laser measured data is accurate within thousands of an inch and enables the processes of manufacturing. Laser measurement technology has developed and been improved over the years to make it possible for the instrumentation to be taken into the field. Using softwares such as verisurf and polyworks complicated profile measurements are made possible. The laser measures very rapidly and using mathematics standard deviation the confidence in the measurement can be determined.

Uses for the accurate measurements and large envelope of measurement capabilities in manufacturing are:

- Laser alignments- of field machining equipment to insure accurate machining in the field, alignment of large equipment to insure axial running and tool alignments.

- Inspection of parts – dimensional inspections of profiles, true position, and general sizes for form fit and functionality to meet tolerances.

- Digital assembly use of laser tracker measurements to place components in complex assembly procedures.

- Equipment, machine and tool calibrations- Calibrating cnc machines linear travels as well as the square of machine geometry.

- Data collection of dimensional information for reverse engineering of components with three dimensional information to complete solid parametric models that can be used to manufactured the component see our reverse engineering page: https://primemachine.com/machine-shop-services/reverse-engineering/.

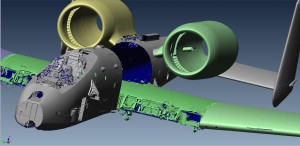

A10 airplane was laser scanned and data aligned to create three dimensional model of the A10 airplane applied use of laser measurement and computer analysis of data.

Laser measurement of C130 airplane. Scanned airplane with laser scanner collected billions points of data to solid reference system, aligned and merged the the data for the three D model.